Even if you didn’t model it in the correct position or know for how the part is going to be machined, The Fusion 360 CAM setup can help set the WCS with the quick selection of an edge to properly orienting the model for the machine.Ī quick definition here – Roughing a part is removing as much material as possible in the shortest amount of time as possible. The first feature we can use in setting up a toolpath is determining a Work Coordinate System (WCS). You considered size and stock material availability, even the position it was modeled it in. So let’s take a step-by-step look at features I wish I had along the way, features I think will become increasingly important to engineers and designers, while keeping Mike’s gentle words in the back of our head. At most, it saves time, material and rework, which helps save… cue the O’Jays. I’m looking at this, not from becoming an overnight CNC success, but to better understand HOW toolpaths are created and how it can be an aide in the product dev process. This, of course, is where integrated CAM comes in. This way, before something is handed off to the shop, the likelihood that it can actually be manufactured will be more than just a guess. What processes make the transition from engineering to manufacturing go more smoothly. True enough, these are things many designers and engineers are not privy to until they’re in the thick of it. I’m so thankful for Mike and the time he took to help me understand the basics of the manufacturing process. Then you’ll know how much someone can bleed on a piece of paper! $H%$*#!”

Rework – Mike: “If I have to redo any of your $#!%, I will beat you with that useless 20-sheet drawing. I smoke with this hand and this one only has three fingers!” Even a basic part is going to have, at the very least, two setups. Tools – Mike: “If I have to change that tool more than twice, I’ll kill you *!$#&%. Think of stock size, and ways to reduce waste!” Materials – Mike: “You’ve got to know what’s available and what’s commonly used, you stupid #$*%ing engineer. When first working in a manufacturing environment, I asked myself, what manufacturing processes do I need to know? And, why do I need to know them? Fortunately, Shop Manager Mike heard me and broke it down for me in simple terms and foul language with three things to think about before slapping model geometry together.

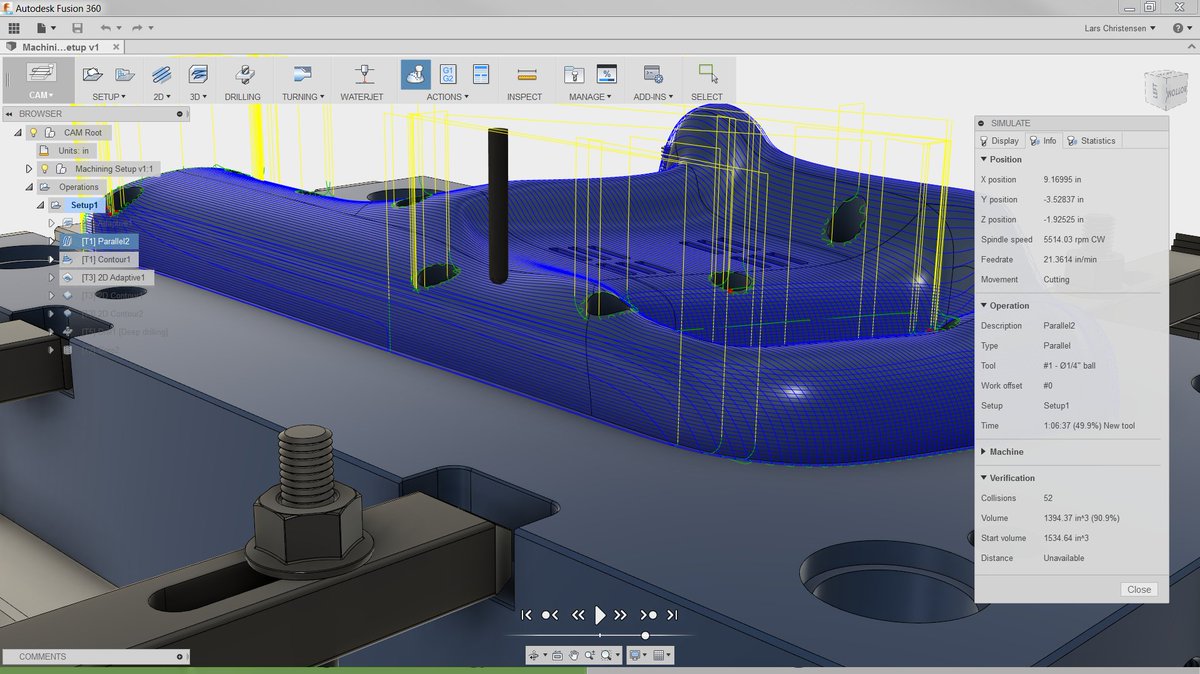

I’d like to talk about the steps to understanding CAM in Fusion 360, but in the context of what it does to help (crank the reverb) ENGINEERING TEAMS. But rather than talk waaaaay out of my proficiency about CAM features like toolpath setup, tool libraries, roughing & finishing, and all things CAM as though I’m Machine Shop Billy flicking cutting oil in your eye, I’ll take a slightly different path.

0 kommentar(er)

0 kommentar(er)